CFRP-AM

Carbon Fiber Reinforced Polymers and Additive Manufacturing

Individualized cost-efficient and sustainable ultra-lightweight structural components The main task of any natural and technical structure is to guarantee functionality and integrity and to be light in order to minimize material and energy consumption over the entire lifetime. Considering that material, function and form are intimately related to one another, structural efficiency can be improved by multi-material approaches, optimal design topology in terms of material orientation and distribution, and integration of functions.

A key challenge is the realization of individualized lightweight solutions with high customer value. The project consortium aims to push the potential of lightweight through the combination of Carbon Fiber Reinforced Polymers (CFRPs) and Additive Manufacturing (AM) technologies.

Scope of Research Activities

Optimal use of carbon fibers

Key Technical Problems to Solve

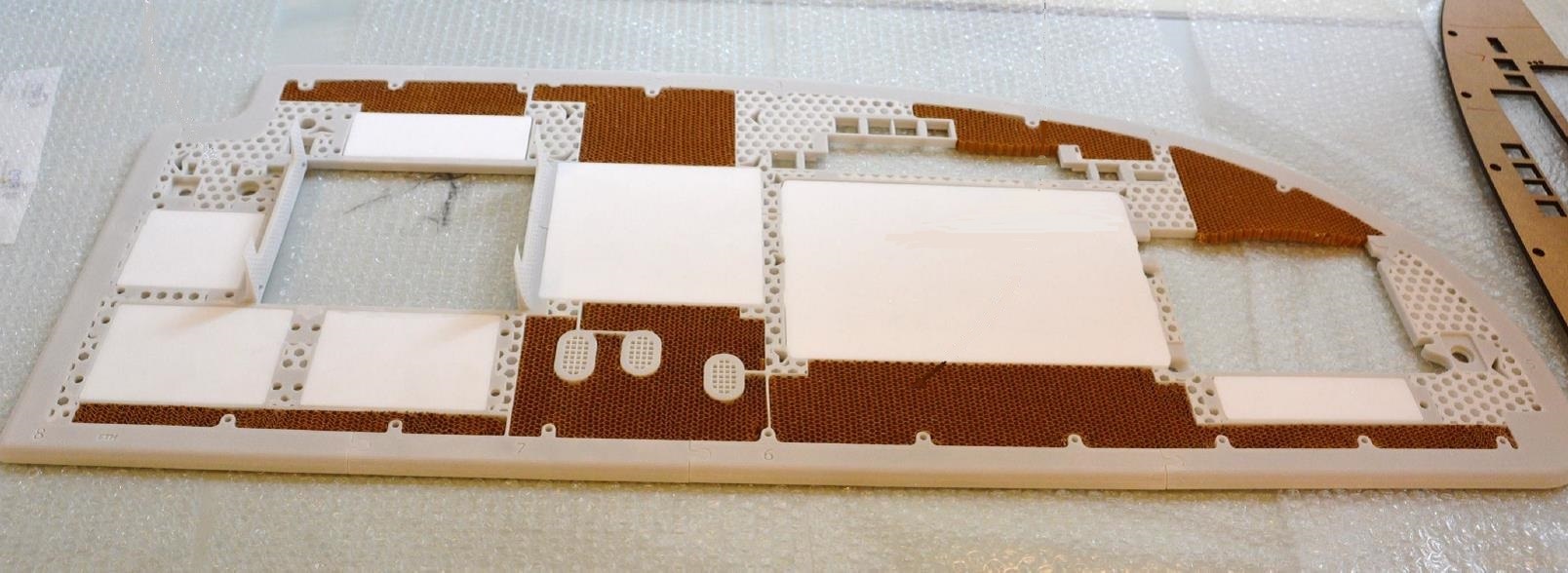

Demonstrators

Linked Scientific Publications

2022

2021

2020

2019

2018

|

Leading Principal Investigator

Project Consortium

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|