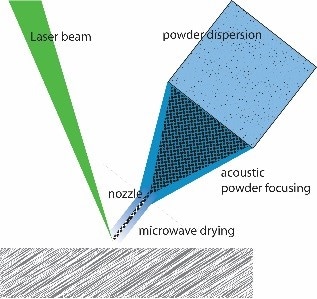

Powder Focusing

Powder focusing for beam induced laser 3D printing

The most flexible 3D freeform manufacturing method is laser melting of a powder jet oriented onto a moving substrate. One example of such an Additive Manufacturing technology is Laser Metal Deposition (LMD). The obtained dimensions of the structures are usually in the millimeter to several tens of millimeter range. Smaller structures are presently limited by several factors including the applied laser spot size, the precision of the mechanical tables, the powder particle diameters (> 20 µm) of flowable powders and the powder jet spot size.

Scope of Research Activities

Key Technical Problems to Solve

Demonstrators

Linked Scientific Publications

2022

2020

|

Leading Principal Investigator

Project Consortium

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|