ClosedLoop-LMUltrafast Laser Closed-loop Manufacturing using mid-IR Spectroscopy

Background and main goal

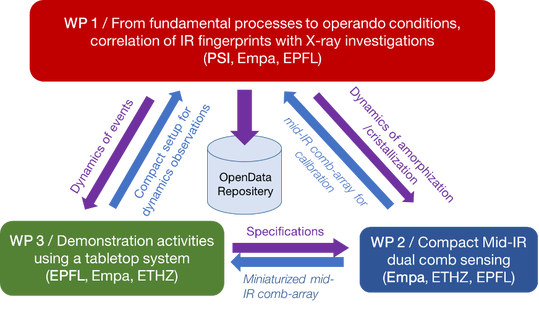

Lasers can be found in numerous manufacturing processes. To date, the vast majority of these processes are performed open-loop: Laser processing parameters are pre-selected to accommodate for inherent variations during production, following step-and-repeat approaches. These methods become rapidly inefficient when it comes to processes requiring a high level of precision and/or having a high level of complexity, for instance, when two-dimensional planar problems are turning into three-dimensional ones. In the ClosedLoop-LM project closed-loop control strategies will be investigated and adapted to ultrafast laser and non-ablative 3D laser processes. Mid-infrared dual-comb spectroscopy will be used to perform in-situ, ultrafast monitoring of structural changes in the material being exposed to the laser. In addition, X-ray experiments at the Swiss synchrotron and free-electron laser sources will be used to gain fundamental information on the dynamic transformation of the material and to guide the sensing and control-loop methodologies. Idea and approach

The ClosedLoop-LM project aims at investigating ultrafast laser-feedback control based on in situ structural material information acquired in real-time, leveraging recent progress in mid-infrared dual comb spectroscopy. From fundamental processes to operando conditions and correlation of IR fingerprints with X-ray investigations:

Compact mid-infrared dual comb sensing:

Demonstrator

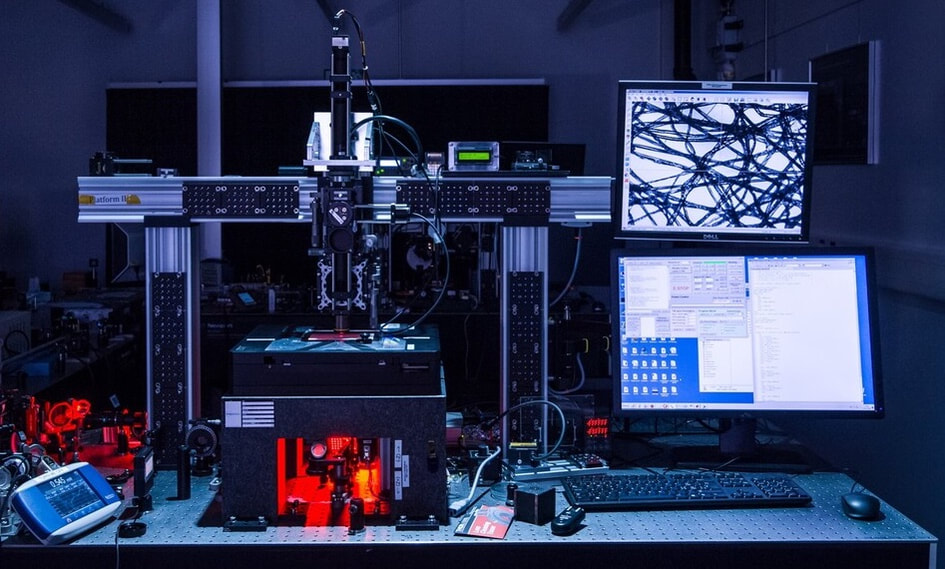

Portable, desktop-sized laser platform for manufacturing and in-situ observations The demonstration platform will consist of three axis moving stages capable of moving the specimens under a stationary laser beam. A single reflective objective will focus the mid-infrared sensing and the machining probe into the specimen. Third-harmonic signals are used for locating precisely the specimen substrate surface. The demonstration platform will be evaluated using three representative laser-induced structural transformations:

Technical challenges

Implementing closed-loop control strategies implies that relevant information from the machining site is retrieved. Here, the main challenges are:

Consortium

Involved and supporting industry partners

Key project data

Linked scientific publications

2024

2023

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|