FUORCLAM

Fundamental Understanding of Oxide Refractory Ceramics and

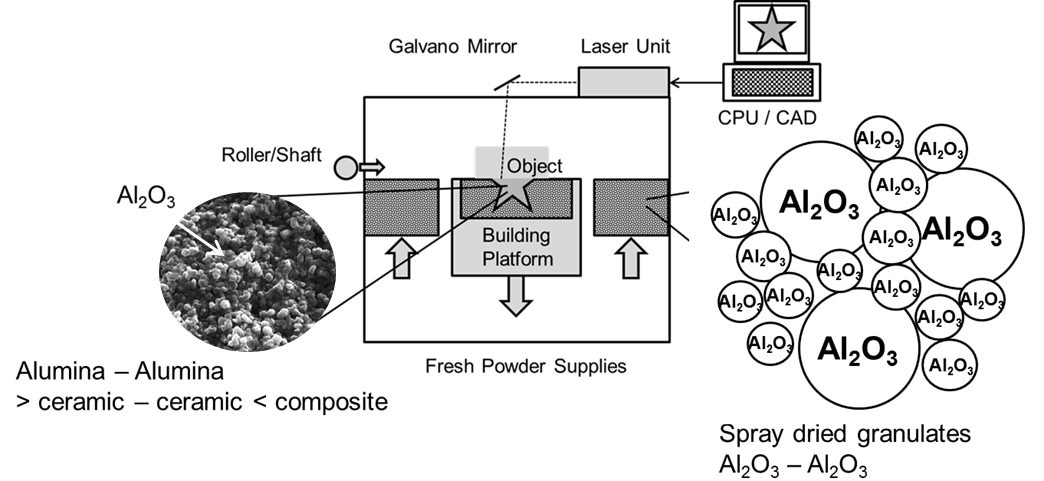

Laser Additive Manufacturing Selective laser sintering (SLS) and selective laser melting (SLM) is already getting a mature technology in metals and polymer processing. In contrary, in high tech ceramics based materials there is no existing SLS process available to consolidate, either by solid state or by liquid state sintering processes, ceramic powders to dense structures with convenient materials properties. The consortium will study the laser interaction of oxide based starting materials and the effect of composite granule composition and morphology on the absorption behaviour of pulsed lasers. The new SLM process will offer the opportunity to create ceramic gradient structures with defined porosities and possible applications as implant materials or as machine parts, where the formation of intimate contacts between metal and ceramic parts is still an issue.

Scope of Research Activities

Key Technical Problems to Solve

Demonstrators

Linked Scientific Publications

2024

2022

2021

2020

2019

|

Leading Principal Investigator

Project Consortium

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|