SMARTAM

Fast Optimization of Additively Manufactured Metallic Parts with a Combination of Adaptive Feedforward Control and Numerical Simulation

Background and main goal

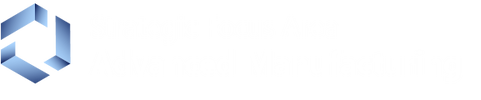

Laser Powder Bed Fusion (LPBF) is considered as the most accurate advanced manufacturing process for metals. It has, however, a number of drawbacks, such as a lack of repeatability and a time-consuming and material and machine dependent optimization of processing parameters. In the SMARTAM project, these issues will be addressed by developing an adaptive feedforward control of laser parameters. Process parameters will be defined from a Machine Learning (ML) model built from a multiscale numerical simulation of the LPBF process. The ML model will be progressively improved by using information, such as local temperatures and acoustic emission, collected during fabrication. With this strategy, optimal processing parameters will be obtained after LPBF manufacturing of the first part. The quality of the part will be measured from both defect content and tuned microstructures. The approach will be tested on a miniaturized LPBF device, which has the advantage of providing additional experimental information from an X-ray beam. It will also be applied to full-scale LPBF machines. Idea and approach

The novelty of the project comes from the development of an adaptive feedforward control of laser parameters based on an iterative scheme:

Additional experimental information will be provided by operando LPBF experiments using X-Ray diffraction and imaging. Together with the two-scale CFD / FEM simulations, this will help understanding the link between processing parameters, defects and microstructures. The two-scale numerical model will be calibrated using the results from the operando experiments and then applied to full-size samples fabricated in a standard LPBF machine. Improvements of the ML model beyond the first iteration will rely on the ability to connect the recorded experimental information to the required change of laser parameters. The ML procedure will be aided by the knowledge gathered in the detailed operando LPBF experiments. Technical challenges

Optimization of LPBF process parameters is often based on trial and error. This approach is not only time consuming but also provides a solution only for a given part and material. No general procedures have been derived to ensure optimal defect content and microstructures, when moving from:

An established solution to correct defects ‘on the fly’ is currently not available. This leads to a lack of repeatability which is a major concern especially for certification aspects, e.g., for watch and jewelry applications. Consortium

Involved and supporting industry partners

Key project data

Linked scientific publications

2024

2023

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|