MANUFHAPTICSManufacturing of Actuators Integrated in Active Exoskeletons

Background and main goal

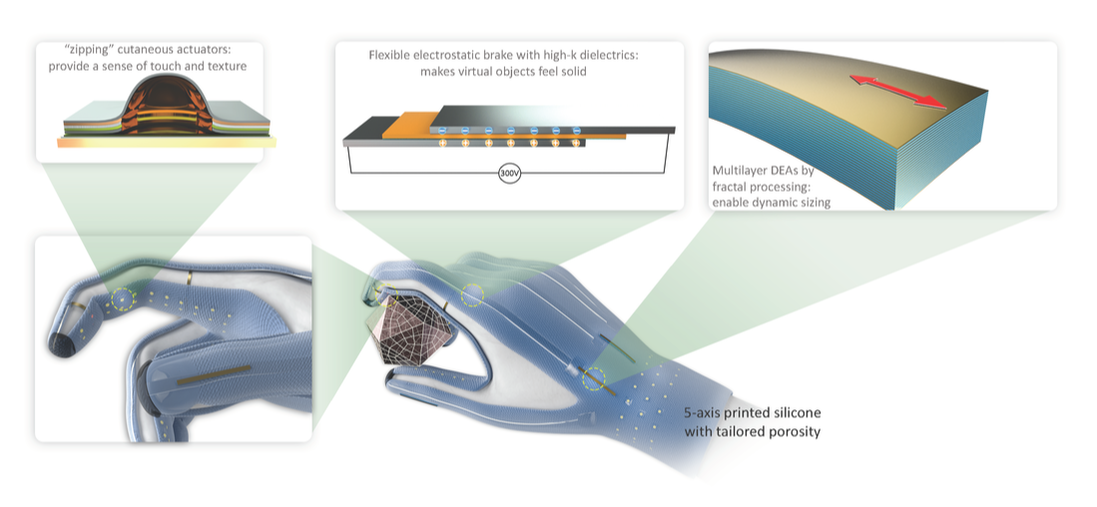

In several application areas, such as assistive devices for rehabilitation, soft exoskeletons to support active lifestyles, and haptic devices for teleoperation and for immersive virtual reality gaming, there is a need for compliant active wearables. However, despite rapid progress in additive manufacturing of soft structures, the direct integration of dense arrays of electrically-controlled actuators in printed wearables remains elusive. The main goal of MANUFHAPTICS is to develop novel functional materials and scalable additive manufacturing processes for soft actuators that are directly integrated in an elastomer exoskeleton. Three types of electrically-driven actuators will be fabricated. The main demonstrator will be a digitally manufactured soft glove, making virtual objects feel real. Idea and approach

Novel functional materials as well as multi-material printing and hybrid integration processes will be developed to allow the seamless integration of electrically-driven actuators in active soft systems. This will enable a broad range of complex soft active systems, that require no pumps or compressors to achieve complex operation. The key building blocks of the MANUFHAPTICS project are:

With these technologies, three types of actuators will be developed:

Demonstrator

Digitally manufactured soft multi-modal haptic glove MANUFHAPTIC’s main demonstrator will be a digitally manufactured soft multi-modal haptic glove with arrays of actuators and sensors for augmented reality and virtual reality applications. Actuators distributed over the fingers and hand will deliver touch and feedback sensations as well as orientation and blocking of the movement. Additional sensors will provide information on the position of the hand, with technology coming from the SFA-AM project D-SENSE, in which piezoresistive and capacitive soft sensors are produced by direct ink writing. Technical challenges

Consortium

Involved and supporting industry partners

Key project data

Linked scientific publications

2023

2022

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|