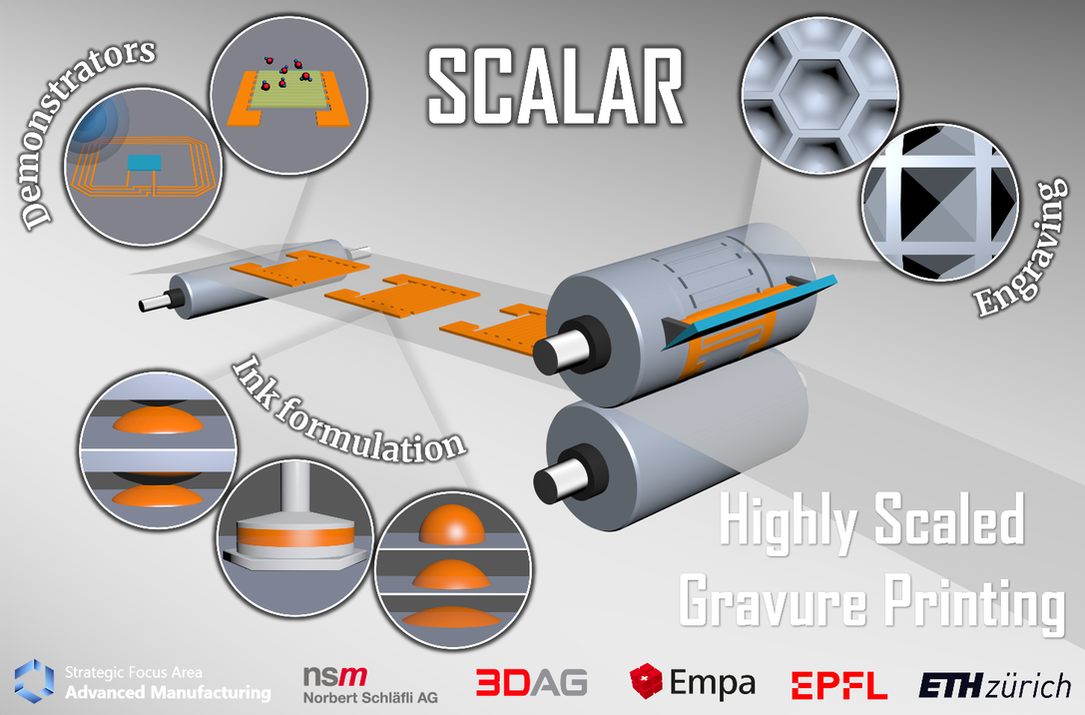

SCALAR

Highly Scaled Gravure Printing

Background and main goal

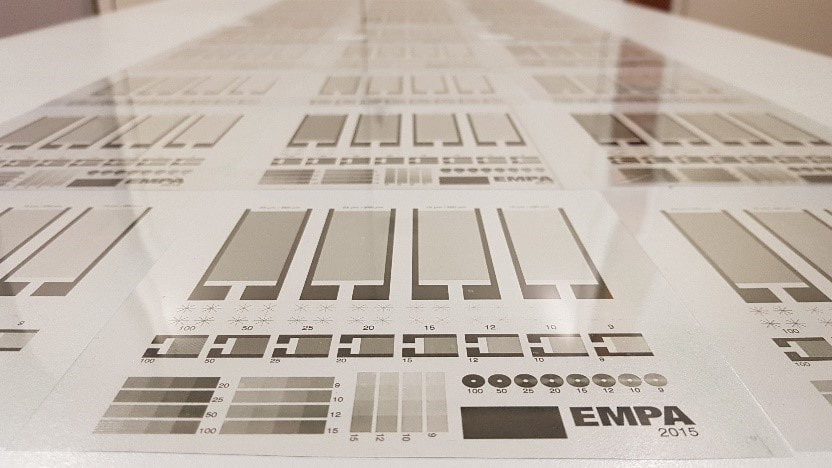

Gravure printing has served the graphics and art industry over decades. Here it offers two major benefits: (i) the printing resolution exceeds the resolving capability of the human eye, and (ii) the high printing speeds that can be reached. In proof-of concept studies researchers demonstrated that electro-opical devices and functional coatings can be printed as well. In SCALAR, gravure printing will be developed further to close the gap between the laboratory scale devices and printing of devices at industrially relevant speeds. Printing of high resolution features at high speed is possible because during ink transfer the gravure cylinder is in direct contact with the substrate. This on the other side poses strong requirements to instrumentation, process parameters, gravure cylinder design and engraving method and ink. The project will push the leading role of the Swiss printer and cylinder manufacturers in the field of gravure printing. Idea and approach

Gravure printing as such is a complex process, improvements can only be expected when looking at the interplay of printer configuration, gravure cylinder pattern and the rheological properties of the ink. The SCALAR consortium combines the required complementary expertise to tackle this task by combining the following individual approaches:

Demonstrators

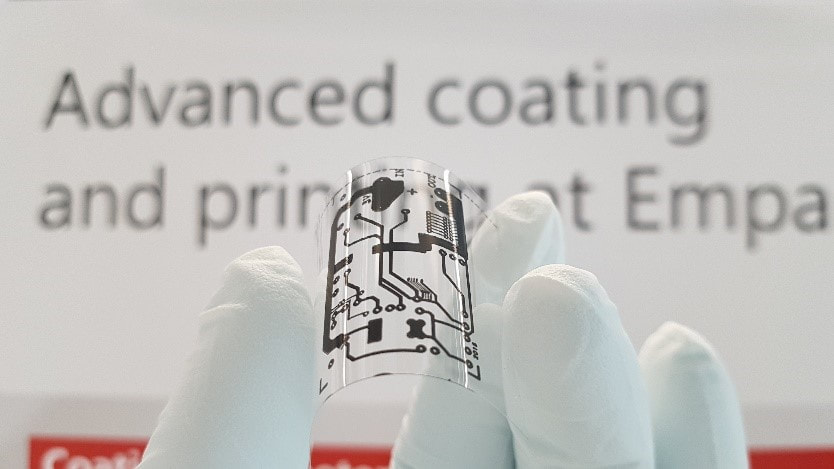

Transparent micro-/nanomesh electrodes Gravure printing will allow the production novel transparent micro-/nanomesh electrodes which can find use in large area applications. For example, in the field of e-mobility, the autonomy of electric vehicles can be increased if heating and cooling energy can be reduced by smart solar radiation management through electrochromic windows Novel applications in health and environmental monitoring Large volume printing of sensors will enable novel applications in health and environmental monitoring. Prerequisite is the miniaturization of the supporting printed circuit board. High precision printing in combination with new ink developments will allow to print embedded components (resistors, capacitors and inductances) to realize sensing systems. Technical challenges

Currently available high throughput printing techniques can print at high speeds but are restricted to features sizes above 10 micrometers, while higher resolution techniques are limited in speed. Thus, the key challenge for highly scaled gravure printing is two-fold:

Consortium

Involved and supporting industry partners

Key project data

Linked scientific publications

2023

2022

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|