SOL4BATFabrication and diagnostics of stable solid-solid interfaces for next-generation Li-ion batteries

The explosive growth of e-mobility has caused a massive demand for Li-ion batteries. More than 20 so-called gigafactories have been announced in Europe to scale up the fabrication of the current generation of Li-ion batteries (LIBs) based on graphite anodes, intercalation-type metal oxide cathodes, and organic liquid electrolytes (Gen 2).

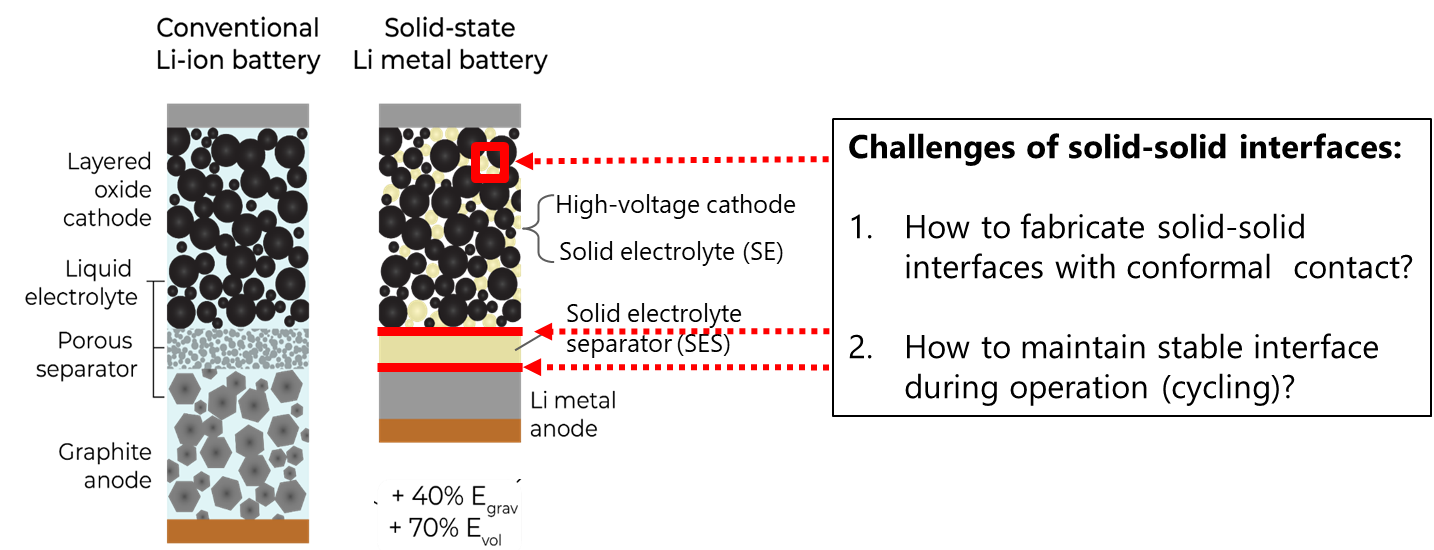

At the same time, many battery and automotive industries have already formed strong alliances to develop solid-state batteries (SSBs) of Gen 4. In addition to the improved safety aspects by replacing the liquid organic electrolyte with a solid Li-conducting electrolyte, the SSB technology offers the advantage of using metallic lithium on the negative electrode. A higher gravimetric energy density of over 450 Wh/kg should be feasible as well as reduction of charging times from the current 30-40 minutes to less than 15 minutes. However, there are several technological and manufacturing challenges on the way to demonstrate a SSB (right) with performance exceeding that for the state-of-the-art Gen 2 batteries (left). Many of these are related to the use of metallic lithium. Another group of challenges is associated with the various solid-state interfaces (SSIs) between ...

Scope of Research Activities

The project aims to investigate whether it is possible to fabricate solid-solid interfaces (SSIs) between solid electrolytes and high-voltage cathode materials, which should remain stable during operation (cycling). The main idea is to employ interlayers at the critical SSIs, which should i) ensure necessary Li-ion transport, ii) release mechanical stresses at SSIs, and iii) suppress undesirable interdiffusion and degradation reactions at the SSIs. The project will follow two parallel design and manufacturing strategies to address the postulated technological challenges:

In addition to the design and the manufacturing of the interlayers, the project team will develop and use new methods to characterize the SSIs and their behavior over time:

Key Challenges and Technical Problems to Solve

Demonstrators

Linked Scientific Publications

2023

2021

2020

2019

|

Leading Principal Investigator

Project Consortium

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|