DiPrintProtect

Digitally Printed Temporary Protective Films for Application in the Watch Industry

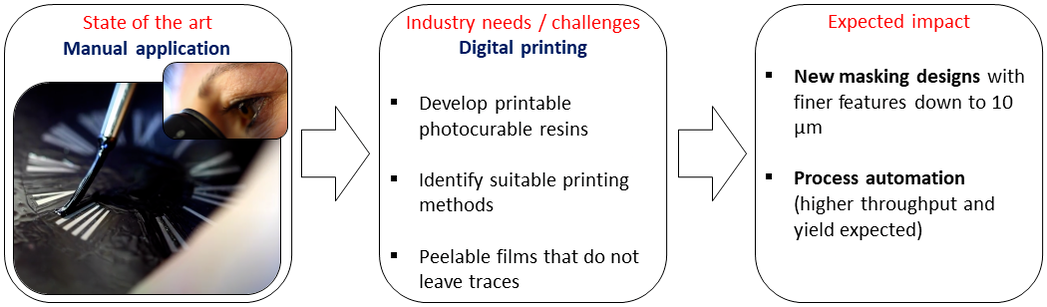

Background and main goal

To date, the Swiss watch industry has relied on handcrafted excellence. While precision manufacturing remains the focus, novel materials and processes are being developed with the potential to replace some of the manufacturing steps that are still done manually with automatic processing. This transformation will not only accelerate production but also allow for new watch designs with higher definition. The DiPrintProtect project aims to replace the manual application of protective coatings within the watch manufacturing cycle with a digital printing process. This will be realized by pursuing three main objectives that reflect industry needs: (i) develop a printable resin to ensure the desired protective function, (ii) identify a digital printing technology with the requested spatial definition down to 10 µm, and (iii) ensure traceless removal of the protection, either by dissolution or preferably by peeling off or delamination. Idea and approach

A scientific breakthrough is anticipated by developing a printable ink based on a reversible photo-polymer that can be cured (hardened) with light and removed later via irradiation with a second wavelength of light without leaving traces. This strategy will be realized in the form of coatings and interfacial (sacrificial) layers. A novel photorheology method will be developed for real-time monitoring of the polymerization-depolymerization reactions. At the core of this technical advance will be a series of photo-resins and adhesion technologies that include photo-activatable and photolabile bonds. In this manner, advanced manufacturing (digital printing via drop-ondemand) can apply the resin and non-invasive optical approaches can cure or remove the coating. Demonstrators

Demonstratators will be realised in partnership with selected Swiss watch industries under the strategic support from the Swiss Association of Horological Research. Technical challenges

Digital printing methods have the potential to fulfill the requirements imposed on the application of protective resins in serial production. However, research is needed to find sets of printable photo-curable resins for desired printability, protection function and traceless removal. The current challenges are:

Consortium

Involved and supporting industry partners

Key project data

Linked scientific publications

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|