PREAMPA

PREcision Additive Manufacturing of Precious metals Alloys

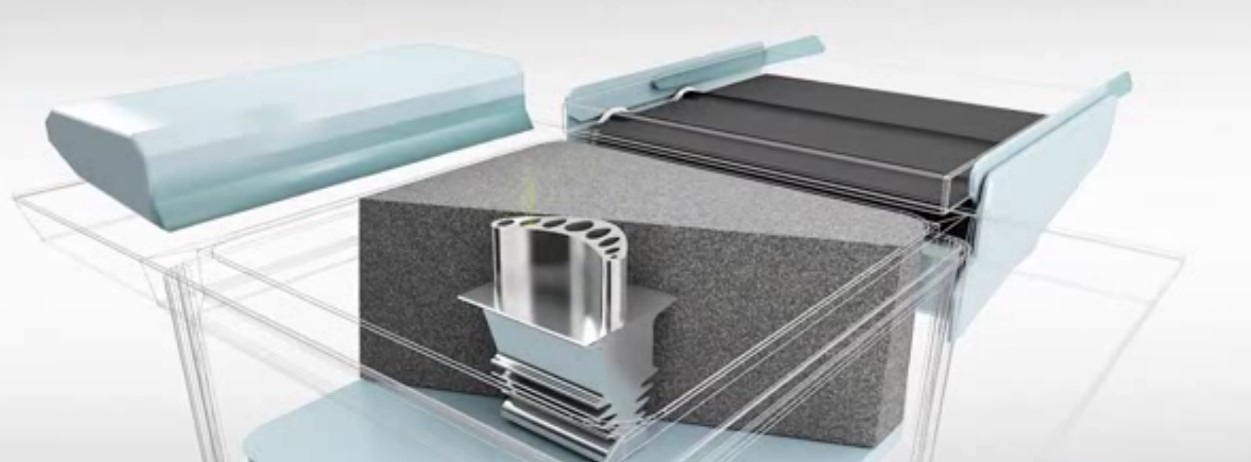

Selective laser melting (SLM) is a powder bed additive manufacturing (AM) technology which allows building components from an alloy powder with complex 3D geometries layer by layer. The application of this technology to precious metals based alloys has been shown to face several challenges, related to their particular combination of optical, thermal and mechanical properties. Resulting parts are notoriously porous, and have low dimensionnal accuracy.

The project consortium aims to improve significantly the processing of these alloys by using lasers with different wavelengths, changing the reflectivity of powders through sacrificial coating and combining the SLM process with a Laser Shock Peening (LSP) treatment. These efforts will be complemented by the development of novel methods for the control and measurement of residual stresses, which are a major cause of process failure and geometrical distortions.

Scope of Research Activities

Material development

Key Technical Problems to Solve

Demonstrators

Linked Scientific Publications

2023

2021

2020

2018

|

Leading Principal Investigator

Project Consortium

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|