Microfluidics

Functional Integration for Rapid Realization of Microreactors and Bio-assays

Background and main goal

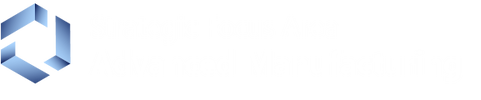

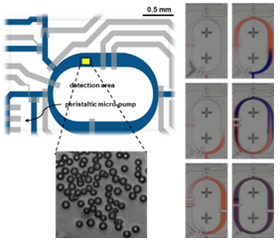

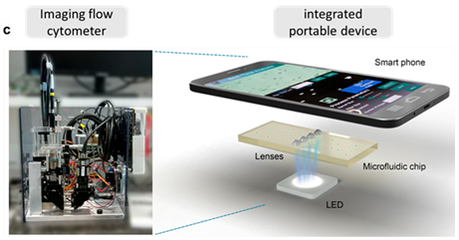

Microfluidic systems have been an important area of focus especially for the medtech and biotech industry. One example is the realization of high-throughput rapid diagnostics where microfluidics allows for the analysis of small volumes of material with the promise of increased assay sophistication and accuracy. However, microfluidics manufacturing as it exists today has several restrictions that are ripe for exploitation through advanced manufacturing paradigms. The Microfluidics project will develop a technology suite for the realization of integrated microfluidic device platforms such as microreactors and bio-assay systems. The technology will be built around novel low-temperature glasses and piezoelectric materials that are suitable for 3D printing and embossing to realize fully-integrated functional systems. Processes will be developed to ensure high-throughput production, including 3D printing and embossing of the novel glass materials, additive manufacturing of active microfluidic components, monolithic component placement and attachment of electronics, along with optical sintering to ensure overall process and material compatibility. Idea and approach

The Microfluidics project will address all issues related to manufacturing viability – from materials development through cost-efficient processes and monolithic integration of components to complete demonstrators:

Demonstrators

Technical challenges

The Microfluidics project will address several challenges that exist in today’s manufacturing of microfluidic systems:

Consortium

Involved and supporting industry partners

Key project data

|

|

An initiative of the ETH Board

|

Participating Institutions of the ETH Domain

|